Gear Grinding

Gear Grinding is very high precision finishing operation constitutes removal of considerable amount of excess material from gear teeth flank. Gear Grinding Process is generally executed on gear teeth after Heat Treatment process to achieve desired Quality Parameters within permissible dimensional tolerences, i.e surface finish as well as surface texture, accuracy in form & profile.

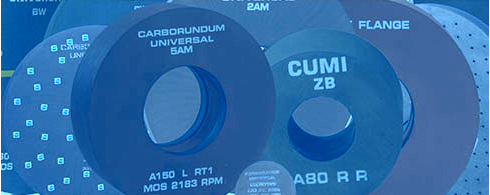

Cumi's Gear Grinding Products are manufactured through in-house state-of-art facility. As per recent advances in Gear Grinding process, CUMI has emerged with next generation high performance Bond as well as special Abrasive. Through special Krystal Bond (V500 & V736) and Micro - Crystalline Abrasives (MSB & 83R), we are very much capable to customize our products to fulfil customer expectations on cost & quality.

Single Rib Gear Grinding

Special Features:

- Reduction in dressing depth as well as dressing frequency; result in higher wheel life

- Higher dresser life due to less wear-out

- Excellent Profile retention of grinding wheel face

- Save more in Grinding Cycle Time

CUMI Product Size:

| OD mm | Width mm | Bore mm |

|---|---|---|

| 80 to 508 | 10 to 125 | 20 to 304.8 |

Multi Rib Gear Grinding

Special Features:

- Superior accuracy on Gear Teeth Profile & Lead

- Controlled stock removal on Gear Teeth flank; save more on Cycle Time

- Save more on dressing cycle time; result more on dresser life

| OD mm | Width mm | Bore mm | Machine Type |

|---|---|---|---|

| 350 | 62/84/104 | 160 | Reishauer OZA/AZA/NZA/Rz362 |

| 275/300 | 125 | 160 | Reishauer RZ400/RZ150/RZ820/RZBASIC |

| 400/450 | 84/104 | 160 | Csepel,Reishauer RZ800 |

| 195/240 | 200/230 | 90/120 | Liebherr LCS200/LCS280 |

| 200/220 | 84/104/150 | 90/120/76.2 | Samputensili S400GT |

Hob Re-sharpening

Shaving Cutter

Gear Honing

Gear Honing Process takes place by rolling off the work piece on cross-axis against Honing Ring. Honing Profile can lead to significant reduction of noise. Power Honing leads to stock removal with sufficient rate which makes pre-grinding process unnecessary or obsolete.

CUMI offers Gear Honing for extremely profiled Honing Ring.

Honing Ring (Vitrified Bond)

CUMI's high Performance vitrified bonds achieve controlled stock removal rate upto 0.1 mm per flank.

Honing Ring (Epoxy Resin Bond)

CUMI's Expoxy resin bond along with a special treated Aluminium Oxide results into controlled as well as high stock removal rate.

WATER SOLUBLES

Water solubles are broadly classified into Semi-synthetic, Synthetic and Emulsions.

RUST PREVENTIVES

CIMGUARD & CUMIGUARD Series are Rust Preventives to give Rust Protection on jobs

NEAT OILS

Milpro and CUMILUBE SL Series are high performance Specially designed products blended from highly refined mineral oil.

FORMING FLUIDS

The MILFORM and CUMIFORM Series of stamping and tube bending fluids provide solutions to a wide variety of metal-forming applications.

CLEANERS

CIMCLEAN and CUMICLEAN series of System and Part Cleaners are designed for Cleaning Machines, Central

These are divided into Vitrified, Resinoid & Rubber products and Thin Wheels and are manufactured by mixing grains with bonding material, moulding them to shape and then subjecting the output to firing or baking in high temperature and finishing the same to desired dimensions. The composition of the product depends on the type of grains and type of bonding materials used. Sizes will vary between 10 mm to 1200 mm with thickness ranging from 1 mm to 650 mm. Bonded abrasives are mostly in the form of wheels but also in other shapes such as segments, sticks etc. Bonded abrasives for internal purposes classified as Standard Products i.e. those products which are made to standard dimensions, grit sizes, shapes and grain / bond composition. These are sold largely through the distribution channel. Non Standard Products are those products which are made to exact requirements of customers. CUMIs product range boasts of over 20,000 varieties of abrasives. Bonded Abrasives are used in diverse applications like floor polishing, fabrication, polishing, off-hand tool grinding and precision grinding of diverse products like crank shaft, balls and razor blade across a wide spectrum of industries ranging from automobile, construction, fabrication, steel, bearing etc.

SNAGGING WHEELS

Cumi’s snagging wheels are made with a special brown Aluminium Oxide.

ROLL GRINDING WHEELS

CUMI has the complete product range to grind various types of rolls.

RESINOID TAPPER CUP WHEELS

CUMI’s Resin tapper cup wheels are designed for grinding of welded joints of metals and stone by means of portable grinders.

RAZOR BLADE GRINDING WHEELS

CUMI’s Razor blade wheels are made of a special resilient bond with fine grit Silicon Carbide, manufactured under a strictly monitored hot press moulding process.

F – TYPE WHEELS

CUMI’s range of nut inserted wheels are the best in the abrasive industry.

FLUTE GRINDING WHEELS

CUMI is one of the very few manufacturers today producing the complete range of wheels for the cutting tool industry.

FINE GRIT RUBBER WHEELS

CUMI was the first abrasive manufacturer to produce Rubber Bonded Control Wheels.

Vitrified Range

TOOL ROOM GRINDING

Tool room grinding wheels find vast applications in the manufacture and regrinding of cutting tools.

SPECIALITIES

Specialities are abrasive stones, sticks, blocks or cylinders of various sizes and cross sections.

INTERNAL GRINDING

Internal grinding is a process of finishing the inside diameter of the component to an accurate size and desired finish.

GEAR GRINDING

Gear Grinding is very high precision finishing operation constitutes removal of considerables.

CYLINDRICAL GRINDING

CUMI’s versatile range of Cylindrical Grinding Wheels are used for a variety of grinding operations.

CRANK SHAFT GRINDING

CUMI’s Crankshaft grinding wheels are made using special, high performance bond systems.

CENTRELESS GRINDING

CUMI’s range of Centreless Grinding Wheels include the versatile and time tested bond systems.

These are manufactured by depositing grains over a backing material like cloth, paper or fibre. depending on the requirement of the customer, the backing material and type of grains will vary. There are various types of grains like sintered aluminium oxide, silicon carbide, zircon, emery and flint. The grains are of varied sizes referred as grits and their sizes also vary from grit 12 to grit 2000. The backing on which these grains are coated will vary depending on the industry and application to which the coated abrasives are supplied. Initially, the grains are deposited over adhesive rich backing materials and jumbos of coated abrasives up to 1000 metres are manufactured. Then, depending on customer order/usage, these jumbos are converted into various shapes like sheets, belts, rolls, discs and flap wheels. The geometry of the product also differs from each other based on application equipment.

Coated abrasives are used in light polishing applications in automobile, auto ancillaries, white goods, hand and power tools, sanitary ware, furniture, fabrication and construction industry.

BELTS

CUMI’s “Supreme” cloth backed wide belts are used for finishing – boards, plywood, solid wood.